Understanding Your Home’s Gas Pipeline System: A Beginner’s Guide

Key Takeaways

- The article emphasizes the importance of understanding your home’s gas piping system, like it is a network of veins that delivers gas for cooking, heating, and water heating. This understanding demystifies the system’s operation, highlighting its role in daily comfort and convenience.

- It discusses various materials used in gas piping, such as CSST, black iron, and HDPE, each with specific advantages. The cost of installing gas piping is variable, depending on the materials used and the complexity of the installation, underscoring the need for homeowners to consider their options carefully.

- The article details the equipment used in gas distribution systems, like gas regulators, compressors, and leak detectors, and emphasizes the importance of safety measures, including regular checks and maintenance to prevent leaks, blockages, and other hazards.

- Highlighting the cost-effectiveness, efficiency, environmental advantages, and safety of gas systems. It points out that natural gas is an economical and cleaner-burning fuel, with modern safety technologies making gas distribution systems more reliable and safer than ever.

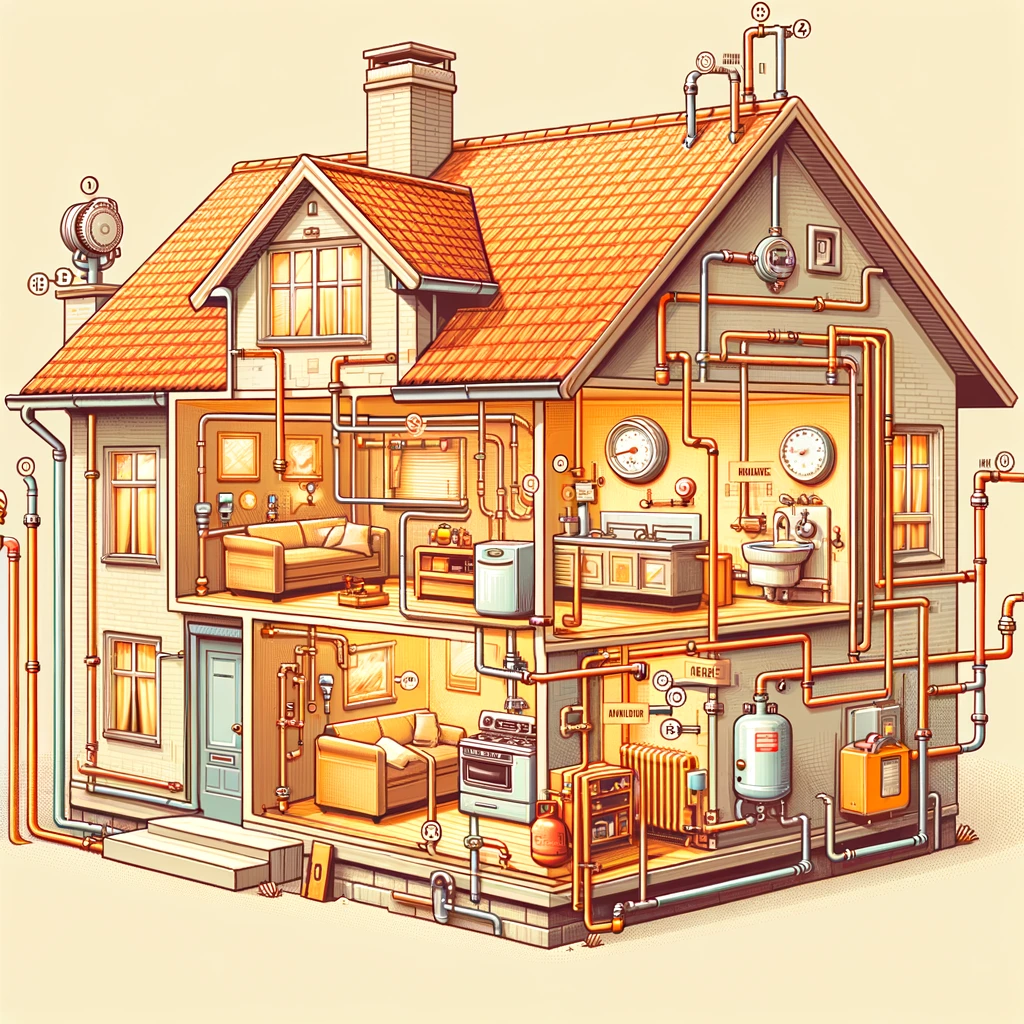

Gas piping is the unsung hero of modern homes, playing a crucial role in day-to-day comfort and convenience.

This system is similar to a network of arteries within your home, and is responsible for delivering gas—fuel for cooking, heating, and even water heating—safely and efficiently from the main supply to where it’s needed.

Understanding the basics of your home’s gas pipeline system, from how it operates to the materials used and the equipment involved, not only demystifies this essential infrastructure but also underscores its significance in ensuring a comfortable, warm, and well-functioning home.

What Is Gas Piping?

Gas piping is like the veins of your home, but instead of blood, they carry gas. This gas is used for cooking, heating, and sometimes even for making your water hot. It’s a network of pipes that safely deliver gas from the main supply to the appliances in your home.

How Do Gas Piping Systems Work?

Think of gas piping systems as a delivery service. They start at the main gas supply, which is like the warehouse. From there, the gas travels through a series of pipes. These pipes are of different sizes.

The bigger ones are for the main routes, and they get smaller as they reach closer to your home appliances, like your stove or heater. This system ensures that gas is available whenever you turn on an appliance.

Gas Piping Cost

The cost to install gas piping can vary. It’s like buying groceries; what you pay depends on what you need. The length of the pipes, the type of material, and the complexity of the installation all affect the price. It can be a small amount for a simple setup or more for a larger home with many appliances.

Types of Gas Piping

There are several materials used for gas piping, each with its benefits.

1. Flexible Corrugated Stainless Steel Tubing (CSST)

Flexible Corrugated Stainless Steel Tubing, or CSST, acts like a bendable straw in your home’s gas system. It easily twists and turns through tight spots. This flexibility means it can be installed quickly, saving time.

CSST is made of stainless steel, which is strong and durable. It’s perfect for running gas lines where rigid pipes can’t go. This makes CSST a top choice for modern gas piping needs.

2. Galvanized Steel

Galvanized steel pipes were once the go-to for gas lines, similar to an old reliable car. They are strong and sturdy, offering long-lasting service. However, over time, better options have emerged, leading to their decline in popularity for gas piping.

These pipes have a protective zinc coating to resist rust. Yet, newer materials outperform them in flexibility and corrosion resistance, making galvanized steel less favored for current gas piping needs.

3. Black Iron

Black iron, the most popular choice for gas piping, is like a heavy-duty truck: strong and dependable. It isn’t true iron but steel with a protective dark coating. This coating helps prevent rust and corrosion, extending the pipe’s life.

Black iron’s durability makes it ideal for gas lines, ensuring a secure, leak-free supply. Its reliability and toughness keep it in high demand for safely transporting gas throughout homes.

4. PVC

PVC pipes, made of plastic, are versatile. They’re common in various applications. For gas, they’re specific to outdoor or underground use. This limitation is due to PVC’s inability to withstand high pressure or heat.

These conditions can cause PVC to fail, posing safety risks. Thus, PVC is chosen for its durability and resistance to corrosion in external or buried environments where pressures are moderate and temperatures are controlled, ensuring safe gas transport.

5. HDPE

HDPE, or high-density polyethylene, is a robust plastic. It’s much stronger than PVC. Used mainly underground, it excels in tough environments. HDPE withstands higher pressures, making it ideal for gas lines. Its toughness means it resists cracks and breaks.

This material is also resistant to chemicals and corrosion. HDPE’s durability ensures long-lasting underground gas pipelines. It’s chosen for areas needing a secure, resilient solution for transporting gas safely under high pressure.

6. Copper

Copper piping stands out for its quality, akin to a luxury car. It’s pricier but excels in performance. Despite its strengths, copper isn’t widely used for gas. The reason is its reactivity; under certain conditions, copper can react with the gas it carries.

This reactivity can lead to safety concerns, limiting its application in gas systems. Copper’s superior durability and resistance to corrosion make it valuable elsewhere, but caution is advised for gas lines.

Gas Piping Problems

Gas piping, critical in homes, can face several issues. The most serious are leaks. Gas is flammable, making leaks dangerous. They can cause fires or explosions. Other problems include blockages and damage.

Blockages stop gas flow, affecting appliance use. Damage to pipes, from corrosion or physical impact, can also halt gas supply. In severe cases, damage leads to leaks. Regular checks are vital for safety.

Maintenance identifies and fixes these issues early. Ignoring them risks safety and disrupts service. Immediate action is necessary upon detecting problems, ensuring a safe, functional gas system in your home.

Equipments Used in Gas Distribution System

The gas distribution system uses several pieces of equipment to ensure gas is delivered safely and efficiently.

1. Gas Regulators

Gas regulators act as critical valves in your gas system. They control gas pressure, ensuring it’s just right for your appliances. Too much pressure can damage appliances.

Too little, and they won’t work correctly. Regulators adjust the high pressure from the main line to a safer, lower level suitable for home use. This ensures efficient and safe operation of heaters, stoves, and other gas-powered devices. Without regulators, managing gas flow and safety in homes would be challenging.

2. Pressure-Reducing Valves

Pressure-reducing valves are safety devices in your gas system. Like regulators, they lower gas pressure. High pressure from the main supply is too much for home appliances.

These valves reduce it to a safe, manageable level. They ensure your gas system works smoothly and safely. By automatically adjusting pressure, they prevent damage to appliances and potential hazards. Their role is crucial for maintaining the right pressure throughout your home’s gas pipeline, ensuring efficiency and safety.

3. Compressors

Compressors are powerful tools in the gas system. They work like pumps. Their job is to push gas through pipes. Gas starts at the main supply, which is far. Compressors move it to your home, overcoming distance.

They ensure gas reaches every appliance, from stoves to heaters. Without compressors, gas couldn’t travel far or fast. They are essential for a steady, reliable gas supply, making modern gas distribution possible and efficient.

4. Flow Meters

Flow meters are the eyes inside gas pipes. They measure gas flow, like checking water from a hose. They tell how much gas passes at any moment. This information is crucial. It helps in billing, showing gas use. It also checks system health.

If flow changes suddenly, there might be a leak or blockage. Flow meters ensure gas distribution is efficient and safe. They are key for managing and monitoring gas supply accurately.

5. Leak Detectors

Leak detectors are safety sentinels in your gas system. They sniff out gas leaks, acting fast. If gas escapes, they catch it. This is vital for safety. Gas leaks are dangerous, risking fires or explosions.

Detectors alert you early, preventing disasters. They monitor 24/7, always on guard. Without them, unnoticed leaks could cause harm. Their role is critical in ensuring your home remains safe from the risks associated with gas leaks.

6. Check Valves

Check valves are one-way doors for gas. They ensure gas flows forward, never backward. This is key for safety. If gas flowed backward, it could mix or build up where it shouldn’t. That’s risky.

These valves prevent such dangers. They’re like traffic cops, directing gas one way. Installed in strategic spots, they keep the gas system safe and efficient. Without check valves, gas systems would face higher risks of accidents and inefficiencies.

7. Filters and Traps

Filters and traps in gas systems act like coffee filters. They catch dirt, moisture, and other impurities. Clean gas is important. Impurities can harm appliances and pipes. They can cause clogs or corrosion. Filters and traps keep gas clean, ensuring it burns efficiently.

They protect your system, extending its life. Regular maintenance is needed to keep them effective. Without them, gas quality would drop, risking damage and inefficiency in your home’s gas supply.

8. Control Instrumentation

Control instrumentation consists of smart tools and devices. They oversee the gas system. Their job is to monitor and adjust. They check pressure, flow, and safety. If something’s off, they respond.

They can turn gas off in danger. This keeps the system running smoothly. It’s like the brain of the gas system. Without these controls, managing gas safely and efficiently would be harder. They ensure gas delivery is reliable, safe, and meets your home’s needs perfectly.

9. Pumps

Pumps in gas systems move liquid gas. Some gas is stored as liquid. It’s denser that way. Pumps push this liquid gas where it’s needed. Then, it’s turned into gas form to use. Pumps handle high pressures, moving gas efficiently.

They’re vital for liquid gas systems. Without pumps, moving liquid gas would be slow, inefficient. They ensure steady, reliable supply from storage to vaporization points, making modern gas usage possible and practical.

10. Safety Valves

Safety valves are critical protectors in gas systems. They watch pressure levels. If pressure gets too high, they act. They open up, releasing excess gas safely. This prevents pressure buildup. High pressure can cause explosions or damage. Safety valves stop that risk.

They’re like emergency exits for gas. Automatically responding, they ensure the system’s safety. Every gas system needs them for protection against pressure-related dangers, safeguarding homes and lives.

Benefits of Gas Distribution System

- Cost-Effective and Efficient: The gas distribution system in homes is designed for efficiency and cost savings. Gas is cheaper than electricity in many areas, making it an economical choice for heating and cooking. It heats up and cools down quickly, providing instant heat. This rapid response not only saves time but also energy, reducing overall utility bills. The system’s efficiency is further enhanced by modern technology, ensuring that gas is delivered where it’s needed without wastage.

- Environmental Advantages: Compared to other fossil fuels, natural gas burns cleaner, producing fewer harmful emissions. This results in lower carbon dioxide levels, making it a more environmentally friendly option for your home. As the world moves towards greener energy solutions, natural gas stands out as a transitional fuel that can help reduce the household carbon footprint. Its cleaner combustion supports efforts to combat climate change, aligning with global environmental goals.

- Safety and Reliability: Advances in safety technology have made gas systems safer and more reliable than ever. Leak detectors, automatic shut-off valves, and corrosion-resistant materials are standard, minimizing the risk of gas leaks or accidents. These systems are regularly monitored and maintained, ensuring they operate safely. The reliability of gas supply, even during power outages, provides uninterrupted energy access, making it a dependable choice for homes.

Conclusion

From the network of piping that supplies gas to your appliances to the sophisticated equipment that regulates and monitors flow and pressure, each component plays an important role in ensuring that your home remains a cozy and welcoming space.

Recognizing the benefits of this system, alongside a basic understanding of its operation, maintenance, and potential issues, empowers homeowners to make informed decisions, enhancing both the safety and comfort of their living environment.

As technology and safety standards continue to evolve, so too will the reliability and efficiency of gas distribution, making it an invaluable resource for homes now and in the future.

FAQ’s

Q1. What are the most common types of pipes used in home gas piping systems?

The most common types include flexible corrugated stainless steel tubing (CSST), black iron, and, less frequently, galvanized steel, PVC (for outdoor or underground), HDPE (high-density polyethylene), and copper. Each has specific benefits, with black iron being the most popular for its durability and CSST for its flexibility in tight spaces.

Q2. How can I detect a gas leak in my home?

Gas leaks might be indicated by a rotten egg smell, hissing sound near gas lines, or dead vegetation near pipelines outdoors. For safety, homes are equipped with gas leak detectors that alert occupants to leaks. If you suspect a leak, evacuate immediately and contact your gas supplier from a safe distance.

Q3. What should I do if I detect a gas leak?

Immediately evacuate the area without turning on lights or using anything that could ignite the gas. Once safely outside, call your gas utility company or emergency services to report the leak. Do not return to the premises until it has been declared safe by professionals.

Q4. How often should gas piping systems be inspected?

Gas piping systems should be inspected at least once every year by a qualified professional to ensure they are in good condition and operating safely. Regular inspections can identify and rectify potential issues like leaks, corrosion, or damage, preventing accidents and ensuring system efficiency.

Q5. Can I install or repair gas piping myself?

Installing or repairing gas piping requires specialized knowledge and skills, and in many places, it’s regulated by law to be done by licensed professionals. DIY repairs or installations can be dangerous and may violate local regulations, risking safety and legality.

Q6. What are the environmental benefits of using natural gas in my home?

Natural gas is a cleaner-burning fossil fuel compared to others, like coal or oil, producing fewer harmful emissions such as carbon dioxide and sulfur dioxide. This makes it a more environmentally friendly option, contributing to lower household carbon footprints and supporting global efforts to combat climate change.