Are Gas Pipes in Walls? (REVEALED)

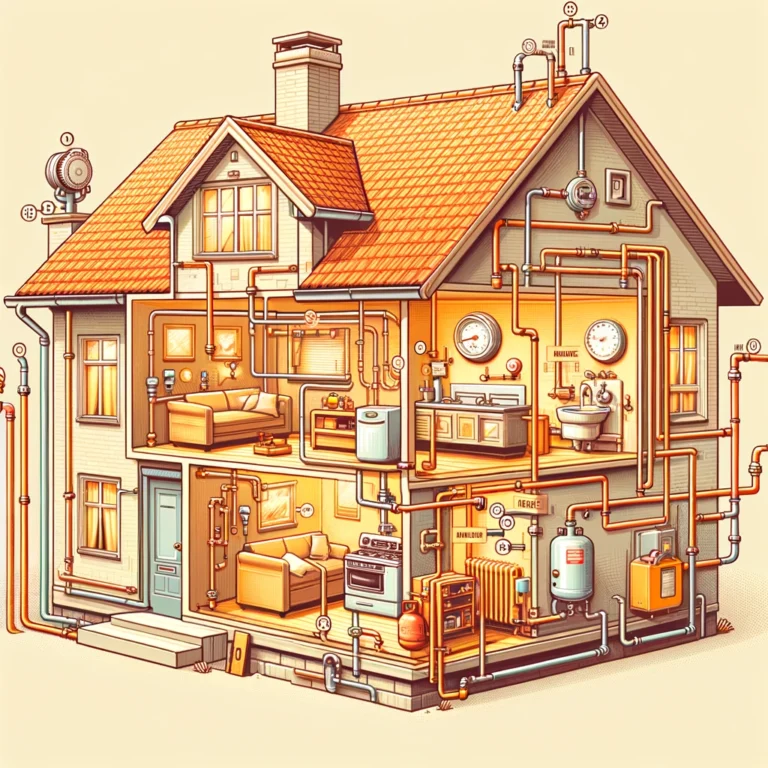

When it comes to the construction of our homes, gas pipes are an essential component in making sure that we can make use of natural resources without compromising on safety.

In this article, we will explore how gas pipe systems are usually placed inside walls and what factors come into play when installing them.

We will also discuss some potential risks associated with having gas pipes within the walls and explain how these can be mitigated.

Get ready to learn more about the hidden secrets behind your home’s construction!

Are Gas Pipes in Walls?

Generally Speaking Yes, gas pipes are typically installed in walls. In residential settings, the pipes are usually installed within a two- to three-inch deep cavity behind the wall’s surface. This helps prevent any potential damage to the pipe and provides an efficient means of delivering gas throughout your home. Additionally, using an insulated material such as foam can help reduce heat loss through the walls and avoid condensations that may form on colder days.

Are gas lines run through walls?

Yes, gas lines can be run through walls.

This is common in many residential and commercial buildings where the structure of the building makes it difficult or impossible to lay pipes outside.

In these cases, a plumber will use an approved wall sleeve that meets local safety codes and regulations to run the pipe inside of a wall cavity that has been properly sealed off from other combustible materials.

In some situations, such as running gas lines behind kitchen appliances, this type of installation may be preferred due to its ability to protect against corrosion over time.

The added benefit is also greater flexibility when it comes to remodeling or changing appliance locations since there’s no need for additional plumbing work each time a move occurs.

It’s important for any homeowner considering this type of project to understand the gravity of the situation and hire only certified professionals who are familiar with local building codes and have experience with installations like this one in order ensure proper usage and get safe results every time.

Benefits of Installing Gas Pipes in Walls:

1. Increased safety:

Installing gas pipes in walls eliminates the risk of gas leaks and potential fire hazards associated with exposed gas lines.

2. Improved efficiency:

Gas pipes installed in walls are better insulated, which helps to reduce energy loss and improve the efficiency of gas appliances.

3. Reduced noise:

Gas pipes installed in walls are better insulated, which helps to reduce the noise associated with gas appliances.

4. Increased convenience:

Installing gas pipes in walls makes it easier to access gas appliances, as they are no longer located in awkward or hard-to-reach places.

5. Improved aesthetics:

Gas pipes installed in walls are hidden from view, which helps to improve the overall look and feel of a home.

6. Cost savings:

Installing gas pipes in walls can help to reduce energy costs, as the insulation helps to reduce energy loss.

Considerations When Running Gas Lines Through Walls:

When running gas lines through walls, it is important to consider a few key factors.

- First and foremost, you should always consult with an experienced professional before beginning any work involving the installation of a gas line.

- Safety must be your top priority when dealing with combustible materials such as natural gas or propane.

- Also, make sure that whatever wall material you are planning on passing through can safely contain and protect the gas line while in operation.

- A wall constructed from brick or masonry may offer more protection than other materials, but check local regulations for specific requirements.

- Never pass a gas line through an exterior wall without proper reinforcement and insulation to prevent outdoor temperatures from affecting its performance.

Be aware of existing ventilation systems in the area where you plan to run the pipe; if there are ventilation ducts nearby, ensure that your new pipe does not interfere with their function by blocking them off entirely or disrupting air flow to other parts of the building.

Lastly, ensure that all connections are secure and properly sealed; this will help mitigate potential damage due to leaks or improper handling during installation or repair work down the road.

Different Types of Piping for Gas Lines:

Gas pipes come in a variety of types, each offering unique benefits and drawbacks. Generally made from copper, plastic, or steel material, piping is used to deliver natural gas from its source to the end user.

Here are some of the most common types of piping for gas lines:

Copper Piping –

Copper is the most popular choice for gas line applications due to its corrosion resistance and low installation cost.

It can also be joined together without special tools or equipment which makes it easy to install.

However, copper does react with certain gases and should not be used when transporting highly corrosive exhausts such as acetylene or ammonia based fuels.

Steel Piping –

Steel pipe offers superior strength over other materials but can suffer from rust if exposed to moisture-rich environments over time.

Therefore it should only be used where an underground application is required and there’s no risk of water damage.

Installation costs are higher than other options but this type of pipework is often preferred by professional plumbers due to it being more durable in the long run.

Plastic Piping –

Plastic piping has become increasingly popular as a cheaper alternative to traditional metal pipes thanks largely to its ease of installation process combined with high levels of durability under normal conditions.

Typically sourced from polyethylene (PE) or PVC (polyvinyl chloride), plastic gas lines can last up to 20 years although they must remain above ground level due their vulnerability towards ground moisture seepage causing corrosion issues over time

Advantages and Disadvantages of Placing Gas Lines Inside Wall cavities:

When deciding whether to place gas lines in wall cavities, there are a number of advantages and disadvantages to consider.

One advantage is that it eliminates the need for unsightly external pipework running around the outside of buildings or through gardens.

This reduces clutter and makes homes look more aesthetically pleasing.

It also offers greater safety from potential hazards such as weather damage or accidental breakage, which can occur with exposed pipes.

Another benefit is that it’s easier to install than other types of piping systems since walls provide an existing structure on which to mount the pipes and fittings.

On the other hand, placing gas lines inside wall cavities has some downsides too.

Firstly, any changes or repairs may require cutting into walls, leaving permanent markings even after they’ve been patched up again – something not every homeowner would be happy with!

Additionally, if done incorrectly by untrained personnel this could cause major issues such as leaks and fires due to inadequate insulation between flammable materials in the cavity.

Lastly, depending on local building codes you may need a professional inspection before you start work to ensure all regulations are followed correctly for maximum safety standards; something else which can add extra time and cost onto projects like this one.

Safety Precautions for Installing a Pipe in a Wall Cavity:

When it comes to gas pipes in walls, safety is of the utmost importance.

Therefore, it is essential that anyone undertaking a project involving a pipe installation takes all necessary precautions.

Fully licensed and qualified:

First and foremost, make sure you are fully licensed and qualified to do so.

Before beginning the job, identify any hazards or potential risks associated with the task at hand and take steps to reduce them as much as possible.

This may include wearing protective clothing, such as gloves and goggles or taking other measures like covering vents near where you will be working.

Adequate ventilation:

Secondly, always ensure that there is adequate ventilation when installing a gas pipe in wall cavities.

It is important for fresh air to circulate throughout the room to prevent build-up of dangerous gases due to combustion processes during your work process.

Additionally, check for existing electrical wiring before cutting into any walls – even if they appear inactive – this could prevent electrocution from occurring as well avoiding accidental damage caused by drilling too deep into an active cable line while trying to penetrate through plasterboard sheets etc..

Finally, never attempt any type of illegal tap offs or modifications which might compromise future maintenance operations on these pipes!

Are gas lines always underground?

Are gas lines always underground? Not necessarily.

Depending on the type of construction, location and local regulations, gas pipes can be located in a variety of places such as walls, floors and ceilings.

In some cases, it may even be necessary to run pipes through an attic or crawlspace.

In residential properties that are connected to the mains gas supply, it is more common for the pipes to be buried underground in order to avoid damaging them during building works or landscaping projects.

The depth of burial will depend on local regulations – usually with depths ranging from one foot up to three feet below ground level.

It is also important to consider any additional load bearing requirements when deciding whether or not a pipe should be laid underground or above ground in walls, floors and ceilings.

For buildings constructed away from the mains supply (such as apartments), running pipes through walls and other areas could be the most practical solution since it eliminates having long runs of exposed piping outdoors which might require regular maintenance due to weathering effects over time.

However, this technique must still comply with relevant safety codes and regulations related to both fire prevention and structural integrity standards

Can you chase a gas pipe in a wall?

Yes, it is possible to chase a gas pipe in a wall.

This involves creating a channel within the wall for the pipes and cables running through it.

The most common way of doing this is by using an angle grinder or drill with special abrasive bits, which can cut out channels without damaging the surrounding material.

Once the channels have been created, they are then filled with fire-resistant insulation and sealed off with fireproof plasterboard or another suitable material to protect against any risk of combustion or leakage.

Chasing a gas pipe in a wall requires particular care as there should be no gaps between objects that could allow gas to escape into other living spaces.

It’s important to ensure that all joints are properly sealed as per regulations set by your local authorities, otherwise you may be putting yourself and others at risk from potential hazardous gases such as carbon monoxide.

If done correctly however, chasing a gas pipe through walls is perfectly safe and can help create more space in confined areas while keeping everything neatly tucked away from view.

It also ensures that maintenance on these pipelines remains easy over time due to their accessibility – helping provide peace of mind for whatever purpose you need them for!

Conclusion: Is it Safe to Install a Pipe In A Wall Cavity?

In conclusion, installing a gas pipe in a wall cavity is generally safe as long as certain precautions are taken.

It’s important to ensure that the walls and pipes are properly insulated so that any heat buildup from the gas line does not cause damage or fire hazards.

Additionally, it is important to make sure there is adequate ventilation for any combustible gases produced by the system.

Lastly, all relevant building codes should be followed when installing a gas pipe in an enclosed space.

With proper installation and adherence to safety measures, most people can safely install gas pipes into their walls without worry of danger.

Very interesting details you have remarked, thanks for putting up.Blog monry