What Happens if a Gas Line is Not Grounded? (Explained!)

A gas line is an essential component of any property, providing a vital source of fuel for domestic and commercial use.

However, not many people are aware that it must be properly grounded in order to function safely and reliably.

In this article we take an in-depth look at why grounding a gas line is so important, the dangers associated with failing to do so, and how you can ensure your own system meets the highest safety standards.

What Happens if a Gas Line is Not Grounded?

If a gas line is not grounded, it could lead to an accumulation of static electricity, which can reach levels as high as 3500 volts. This may cause sparks or arcs that can ignite the gas in the pipe and result in explosions, fires or other hazardous events. Grounding reduces this risk by providing an alternate path for the static electricity to flow into the ground safely.

What is a gas line grounding system?

If you haven’t already noticed, gas comes through a pipe.

This pipe is commonly referred to as a ‘reference circuit’.

A grounding system ensures that electrical current is effectively restrained from entering the gas piping and exiting through any other point than the supply connection.

Having an effective grounding system can be vital – it prevents electric shock for anyone who may come into contact with unpowered parts of your installation such as service panels or jacks.

How is a gas line grounded?

There are a few different methods of grounding a gas line:

1) Direct connection to the earth, through an underground electrode or conduit. This system is the most common, and is typically used in rural areas or areas with unstable soil.

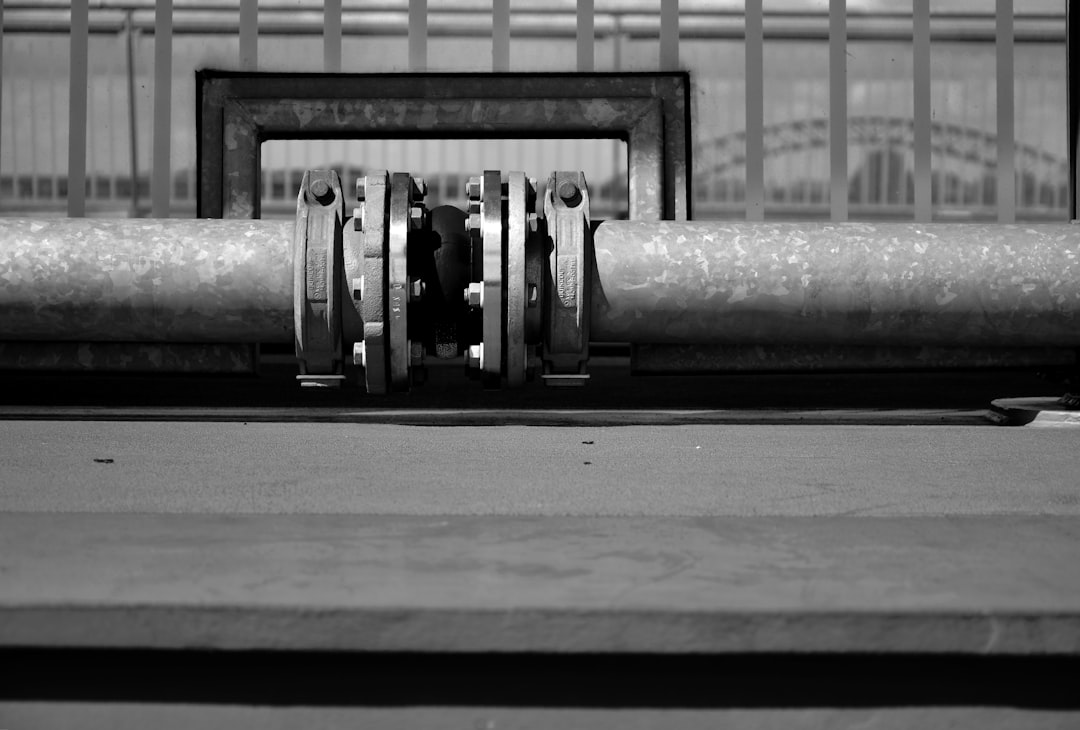

2) Use of a ground rod and galvanized metal shield. This system is usually installed close to the service panel. The ground rod conducts electricity away from the gas piping, and the galvanized metal shield helps protect it from corrosion.

3) Use of a monitoring station to detect potential faults and report them to the utility company.

Where should gas lines be grounded?

Gas lines should be grounded to prevent the buildup of static electricity, which can cause a spark and ignite the gas.

Grounding the gas line also helps protect against electrical surges that can damage the line and cause a gas leak.

The best place to ground a gas line is at the point where it enters the building.

This is usually done by attaching a grounding wire to the gas line and then connecting it to a grounding rod that is driven into the ground.

The grounding rod should be at least 8 feet long and made of copper or galvanized steel.

It should be driven into the ground at least 8 feet deep and should be connected to the grounding wire with a clamp.

The grounding wire should then be connected to the building’s electrical system.

This will ensure that the gas line is properly grounded and protected from any electrical surges.

What are the Dangers of Not Grounding a Gas Line?

If you don’t ground your gas line, it will be susceptible not only to leaking but also electrical faults and direct contact with water.

Unintentional contact with water or immersion in water can potentially result in igniting gas fumes or even causing an explosion!

The most common hazard is accidentally contacting water while filling a tank or hosing down the deck.

This could lead to leakage or even catastrophic loss of life if an accidental spark occurs within the system – leading to a house explosion!

If you detect that your gas line is ungrounded and it’s been several years since installation, we recommend having a professional evaluate it and make any necessary adjustments prior to use.

Potential Hazards of Un-grounded Gas Lines:

1. Fire/explosion hazard due to flammable gas leaking

2. Carbon monoxide poisoning due to incomplete combustion

3. Risk of electrical shock due to lack of ground

4. Risk of corrosion and rusting of gas lines

5. Increased risk of gas leaks due to absence of ground connection

6. Risk of explosion due to buildup of static charge in the ungrounded gas lines

7. Increased risk of fire when using appliances with sparks or arcs

8. Increased risk of malfunctioning electrical devices in the home.

How to Properly Ground a Gas Line to Avoid Potential Hazards?

1: Ensure that the ground connection is made to a metal cold water pipe.

2: Use the proper sized and type of grounding clamp for the gas line.

3: Connect the grounding clamp to the metal cold water pipe in accordance with local codes and regulations.

4: Connect the other end of the grounding clamp to an appropriate ground source such as a metal rod driven into the earth.

5: Make sure that all connections are tight and secure.

6: Test any electrical connections with an ohmmeter or multimeter to ensure that they are properly grounded.

7: Install a ground fault circuit interrupter (GFCI) on any electrical outlets located near a gas line for added safety.

To ensure your gas line is properly grounded, it is essential to tether it with an appropriate grounding rod.

Benefits of Properly Grounding a Gas Line:.

To make things simple, the body of a gas line can be thought of as a conduit.

It connects your home with an outside source – such as a natural gas line or oil pipeline – though it is not essential that it is physically connected to the mains.

If you don’t connect a ground wire to your gas pipe, then you’re skipping out on one major advantage: electrical grounds!

These provide an effective pathway for transferring electricity from various appliances and tools within your abode back into its supply grid.

This in turn reduces strain on your electricity company – resulting in lower rates for both you and them each month – all without any extra effort required!

Some benefits:

1: Prevents gas leaks and explosions due to static electricity build-up.

2: Reduces system noise and interference caused by electrical surges.

3: Reduces the risk of fire due to faulty wiring or equipment failure.

4: Allows for proper operation of electrical equipment without power loss or interruption.

5: Ensures safe operation of electrical and gas systems in the event of a power outage or other emergency.

6: Prevents damage to sensitive electronic components that may be affected by static electricity.

7: Reduces the risk of electrocution and other injuries caused by faulty wiring or equipment failure

Regulations Regarding the Properly Installing & Maintaining a Grounded Gas Line:

It is vital that you ensure that your gas line is properly installed by a licensed plumber.

Failure to do so can lead to hazardous situations, including:

1: Install a shut-off valve within 6 feet of the appliance.

2: Connect the gas pipe to the appliance with a black iron pipe.

3: Use approved fittings and connectors when installing a gas line.

4: Test the gas line for leaks using soapy water or leak detector solution.

5: Ground the gas line using grounding clamps and copper wire.

6: Inspect the piping, connectors, and fittings regularly for leakage and corrosion.

7: Ensure all gas lines are properly labeled indicating their purpose and contents.

8: Have a licensed professional check your gas line for proper grounding and installation each year.

Corrosion of Internal Components:

Corrosion of internal components is an important issue to consider when a gas line is not grounded.

If the line is not properly insulated and metal fittings are exposed to moisture, corrosion can occur as metal reacts with moisture in the air.

This type of corrosion can lead to rusting, weakening of joints and fittings, gas leaks, and potential safety hazards if left unchecked.

It’s important that all parts of the system be inspected regularly for signs of deterioration or damage due to corrosion.

Regular maintenance such as cleaning out debris from pipes, checking for signs of wear or tear on hoses and valves, inspecting tightness at connectors, replacing worn parts with new ones made from material that won’t corrode easily (such as stainless steel).

Applying protective coatings like paint or enamel around external surfaces where possible – these are all steps one should take in order to prevent corrosion-related problems with a gas line installation.

In addition, it’s recommended that grounding wires be installed whenever practical in order to provide additional protection against electric charge buildups which could result in severe equipment failures over time due to electrolytic effects caused by galvanic corrosion between different metals used in the system setup.

Conclusion:

The most common misconception about gas line bonding is that it is comparable to running an extension cord from the outlet.

In reality, however, gas line bonding is more akin to a direct connection from the appliance itself – an option that should not be taken lightly!